SUCCESSFUL UPGRADE OF THE EXTRUDER AND CONDITIONER SYSTEM AT CARGILL DONG THAP

The extruder and conditioner system is a crucial component in animal feed production, directly influencing product quality and operational efficiency. Recognizing the significance of these systems, Cargill Dong Thap, a leading animal feed producer in Vietnam, partnered with DPTA to upgrade its system. This upgrade represents a major step forward in optimizing operations, ensuring safety, and improving product quality, contributing to the sustainable growth of Vietnam’s livestock industry.

Scope of the Upgrade

1. Supply of Flow Meters and Steam Control Valves

• Accurate measurement of steam flow and efficient control of the steam system optimize energy use and ensure process consistency.

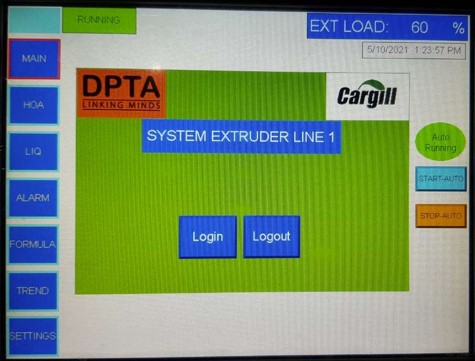

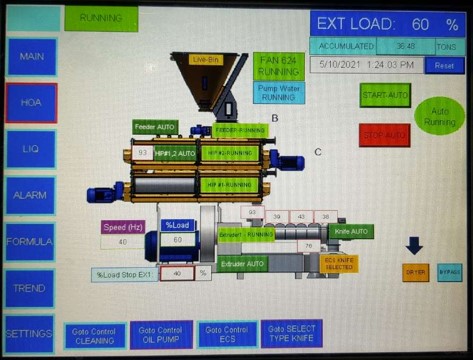

2. Supply of Rockwell PLCs and HMIs

• The advanced Rockwell PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) enable precise automation, easy monitoring, and smooth parameter adjustments.

3. Design of the Automated Control System and Steam/Water Piping

• The control system and piping network were designed according to Cargill Dong Thap’s specific requirements, streamlining operations, reducing manual intervention, and improving worker safety.

4. Installation of In-Wall Piping and Instrumentation

• Aesthetic and efficient in-wall piping installation ensures safety while optimizing the plant’s workspace.

5. Control Panel Installation

• The control panel, designed for ease of use, enables operators to monitor and control the entire system efficiently.

6. System Programming and Commissioning

• DPTA experts programmed and commissioned the system to meet Cargill’s operational needs, ensuring stable and efficient performance.

Practical Benefits of the Extruder and Conditioner System Upgrade at Cargill Dong Thap

- Efficient System Monitoring and Control: The automated system ensures precise monitoring and control of operational parameters, promoting safety and improving efficiency.

- Optimized Production Processes: The system is programmed to optimize production workflows, minimizing material, energy, and time waste, thereby increasing productivity and product quality.

- User-Friendly Interface: The intuitive HMI interface makes it easy for operators to adjust parameters and manage the system, saving time and effort.

- Cost and Energy Savings: The automation system reduces operational, maintenance, and energy costs, offering long-term economic benefits for the business.

- Increased Production Efficiency: The enhanced system boosts productivity and product quality, meeting growing market demands and strengthening Cargill Dong Thap’s competitive position.

The extruder and conditioner system upgrade project at Cargill Dong Thap is a testament to the effective collaboration between DPTA and businesses in the animal feed production industry. The new system enables Cargill Dong Thap to enhance production efficiency, reduce costs, and ensure plant safety. DPTA is committed to continuously delivering advanced automation solutions, helping customers optimize their operations and achieve business success.

Bài viết liên quan

- UPGRADE OF KILIAN E150 TABLET PRESS: NEW CONTROL CABINET UTILIZING B&R’S HYPERVISOR TECHNOLOGY AND ZENON SCADA ENHANCES PRODUCTION EFFICIENCY

- UPGRADE OF HMI WITH ZENON SCADA: A COMPREHENSIVE SOLUTION FOR HASAN IN ITS GLOBAL EXPANSION PHASE

- SCADA SYSTEM AT INSEE THI VAI: A COMPREHENSIVE SOLUTION FROM DPTA

- ENHANCING EFFICIENCY AND PROVIDING COMPREHENSIVE SAFETY SOLUTIONS FOR CARGILL VIETNAM

- CARGILL TIEN GIANG & LONG AN BOOST OPERATIONAL EFFICIENCY WITH A COMPREHENSIVE PCS SYSTEM

- UPGRADE OF THE CONTROL SYSTEM FOR THE FETTE P2100 ROTARY TABLET PRESS

Online:

Online:  During the day:

During the day:  In month:

In month:  Total access:

Total access: